THE SOURCE FOR PNEUMATICS

Air Compressors

Air compressors are the first piece in the pneumatics puzzle. They are responsible for taking ambient air and pressurizing it (compressing it) to drive your air tools. From models that can be thrown onto the passenger seat of a truck and carried to a job site to gas and diesel-powered types for fleet maintenance to permanently-installed models that are designed for constant high-demand operations, the size and type of compressor needs to be tailored to your specific application.

Air Tools

Air tools are what gets the job done. Offered in a wide range of designs and uses, if you have it in a corded or battery-powered version, there’s a pneumatic model that is just as powerful, and many times MORE powerful, but lighter and with a longer service life.

Dryers, Parts & Accessories

Parts and accessories are used to enhance, customize, monitor, and maintain your pneumatic system to keep it operating at peak efficiency with limited down time. Dyers remove condensation, water, & contaminate accumulation which prevents freezing, reduces microbial growth & improves the service life of the system. Other accessories include valves to regulate air flow, gauges to monitor pressure; and couplings & nipples connect hoses to the system and to tools.

Top Pneumatics Brands

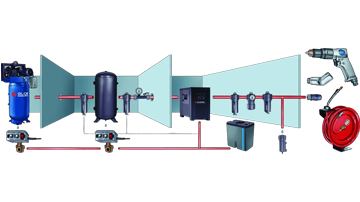

How Does a Pneumatic System Work?

A pneumatic system can be broken down into five essential components that compresses, stores, controls, delivers, and uses air that is taken from the environment.

- Air Compressor: Pressurizes air

- Reservoir: Stores the compressed air

- Valve(s): Allows the air to flow

- Lines & Hoses: Deliver the air to tools

- Pneumatic Tools: Uses the air to perform a job or action

From deburring grinders to jackhammers to automated machines and excavators, many of your favorite products and places were built using pneumatics. Pneumatics is the process of pressurizing ambient air and delivering it to one location, or multiple workstations, in order to drive tools and machinery. Here at Global Industrial® we supply a wide assortment of compressors, tools, and accessories to help your business get the job done. We stock all your favorite brands plus a full line of private label products to fit your needs…that won’t break the bank.